This module computes, for compartments defined with

Layout, tank capacities and corresponding COG for an arbitrary list/trim combination, if required also with temperature correction to account for expansion of cargo or tank structure. These results can be utilized in a cargo/ullage report or be exported to a loading condition.

Specify list and trim

An input window pops up, where the following data can be given:

- Trim in meters (Trim by bow positive), which is the difference in draft on the FPP and the APP (Tfpp - Tapp).

- Angle of inclination in degrees only positive angles can be filled in here.

- The above given heeling angle is to PS or SB.

- Mean draft. This draft is read out by the draft sensor, which is an option in the context of LOCOPIAS. For calculating the tank capacities only, it is not required to give a draft.

Calculate tank particulars

An input screen appears for defining all tank particulars, such as sounding or ullage, volume, density and weight. If one of these items is changed, the other items will be adjusted automatically. The ullage can only be used if a sounding pipe has been defined for the specific compartment (for which reference is made to Sounding pipe). In the alternative window the LCG, VCG, TCG and FSM can be read. By pressing <Enter>, with the cursor on the line of a compartment, a number of particulars can be defined for the specific compartment:

- Tank name

- As defined in the LOCOPIAS vessel model.

- Include this tank in ullage report

- If this compartment should be included in the cargo/ullage report (for an example see Print Cargo/Ullage report on screen) then this field should be set to ‘yes’.

- Product (substance)

- The name of the product, which will be used in the cargo/ullage report.

- Conversion table

- For the calculation of the cargo weight of heated hydrocarbons, the following conversion tables are available:

- No temperature correction.

- Correction factor per degree. The ‘Volume Correction Factor’ is calculated according to the defined temperature and the correction factor per degree (coefficient of expansion).

- Volume Correction Factor. The ‘Volume Correction Factor’ can be defined directly.

- Table 54B. The ‘Volume Correction Factor’ is determined according to ASTM table 54B.

- Table 55. The ‘Volume Correction Factor’ is determined according to ASTM table 55.

- Data link

- This is the value that is sent by the tank measurement system ( Import tank data from tank measurement systeem). The data link value is for checking purposes only.

- Temperature

- The standard temperature is 15° Celsius. The volume is determined at this temperature. The actual temperature of the substance can be defined here.

- Volume (not corrected for expansion)

- This is the volume that is calculated according to the sounding or ullage for this compartment. This volume comes from the previous window with the list of all the compartments.

- Density at 15° Celsius (in air)/(in vacuum)

- The density of the substance at 15° Celsius can be defined here. If the density in air is defined, the density in vacuum is calculated automatically. These two densities are connected to each other and cannot be defined separately.

- Correction factor per degree Celsius

- This factor is used if the conversion table ‘Correction factor per degree’ has been selected, and calculates the volume correction factor.

- Volume Correction Factor

- This factor can be determined with four different methods:

- This factor is defined manually, using conversion table ‘Volume Correction Factor’.

- This factor is calculated with the correction factor per degree and the difference between the standard and actual temperature. The conversion table ‘Correction factor per degree’ must be selected.

- This factor is read out from the conversion table ‘Table 54B’.

- This factor is read out from the conversion table ‘Table 55’. This factor corrects the density at 15° Celsius of the substance for the actual temperature.

- Temperature Expansion Factor

- This factor corrects for the expansion of the tank at a higher temperature than 15° Celsius. This factor is calculated automatically and cannot be defined manually.

- Density at {defined temperature} degrees

- Density at 15° Celsius × Volume Correction Factor.

- Residue On Bottom (ROB)

- Volume of the residue which will be subtracted from the volume of the tank contents.

- Density × Temperature Expansion Factor

- Density at 15° Celsius × Volume Correction Factor × Temperature Expansion Factor.

- Weight

- The weight is calculated according to: Volume (not corrected for expansion) × Density at 15° Celsius × Volume Correction Factor × Temperature Expansion Factor.

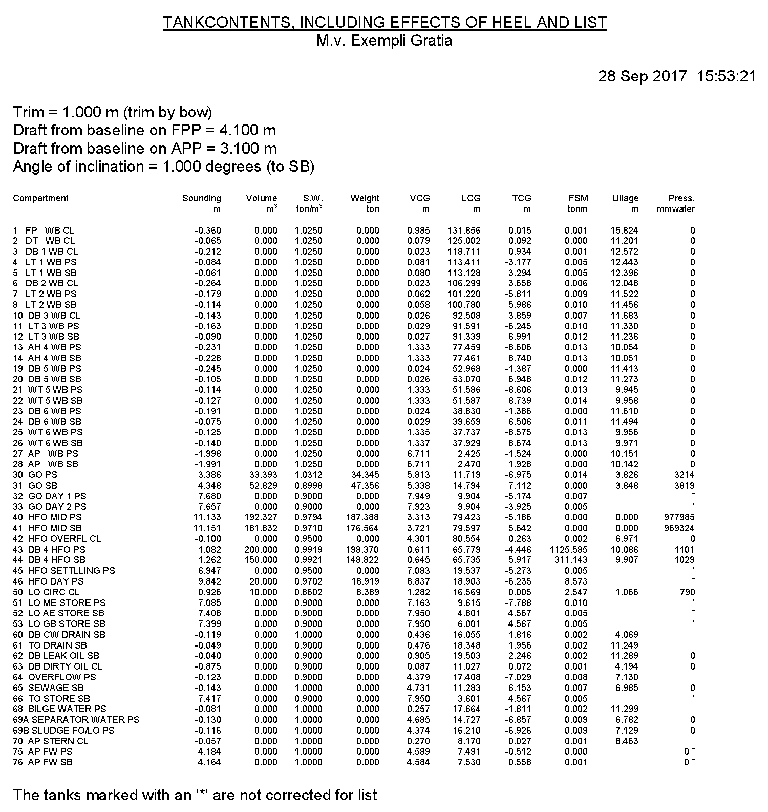

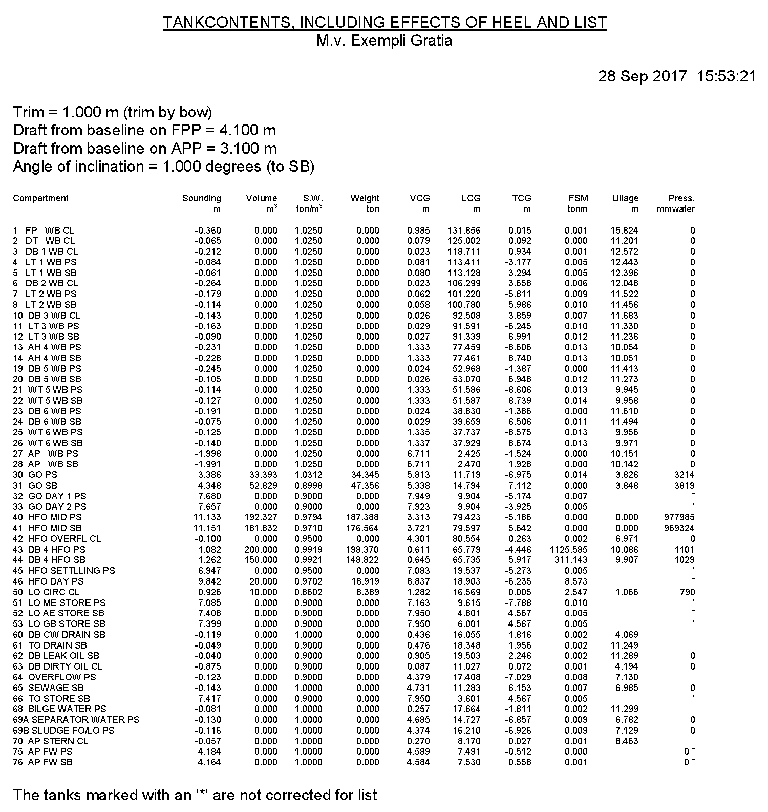

Print all tank particulars on paper

With this option the tank volumes etc. (the same as in the input window of the previous option, see Calculate tank particulars) will be printed. An example is pasted just below.

Table with tank volumes and COGs.

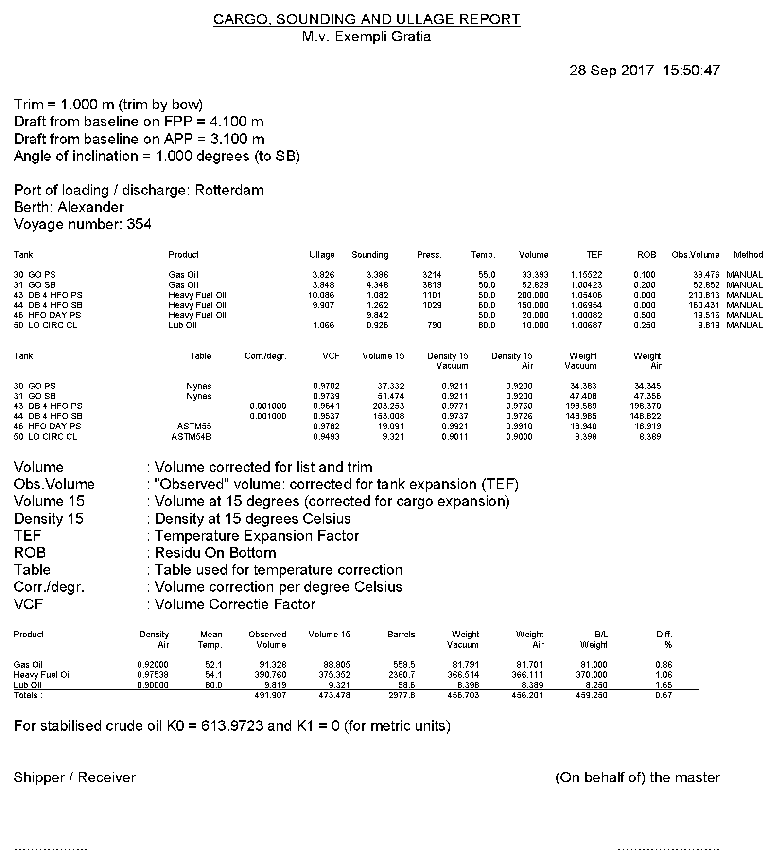

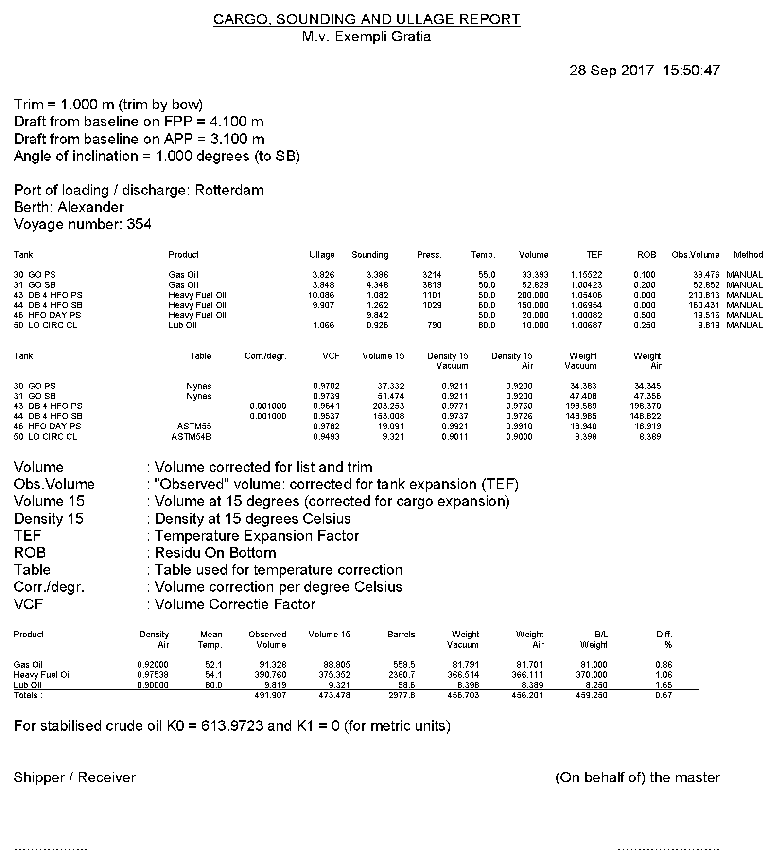

Cargo/ullage report, and historical cargo summary

Print Cargo/Ullage report on screen

This option allows you to print an overview of all onboard cargoes, including their weight, temperature effect, sounding and ullage etc., see example below. This list includes only those tanks of which the detail particulars (as discussed in Calculate tank particulars), at the second row ‘include this tank in ullage report’ is switched on. Before this report is created some more questions might be asked, such as the Bill of Lading weight, and whether this list should be stored at the historical cargo summary.

Example of a cargo/ullage report.

Print Cargo/Ullage report on paper

The same as previous option, albeit with output to paper.

Print historical cargo summary

View and maintain historical cargo summary

These options will speak for themselves.

Export tank data to a loading condition

A list of all defined loading conditions appears. One of these loading conditions can be selected. The selected loading condition will be copied and the tank data of the sounding module will be sent to this copy. The name of this new loading condition will be: name of selected loading condition + ‘tank reading’ + date + time.

Import tank data from tank measurement systeem

With this option the soundings or ullages of the tank measurement system can be read out and processed in the list of all tanks ( Calculate tank particulars).

Up-to-date overview of filling and flow rate per tank

This option opens a window in which the current filling and flow rates are displayed for each tank, as well as the remaining time until the desired filling percentage will be reached. These values are refreshed by default every five minutes, but that interval is adjustable. Obviously, this option can only work if there a connection with a tank measurement system is available.