|

PIAS Manual

2025

Program for the Integral Approach of Shipdesign

|

|

PIAS Manual

2025

Program for the Integral Approach of Shipdesign

|

At the start of Loading, all weight items are checked for references to tanks that have been removed. If this occurs, a choice must be made of what to do with those specific weight items. There are a few possibilities:

If “don't do anything automatically” is selected, and these references have not been resolved manually, then this popup will return the next time Loading is started.

Here appears the Graphical User Interface (GUI), which can be considered as the central command window of Loading, see Main window layout. This GUI is not strictly indispensible, without it is very well possible to navigate through Loading with all functions and menu options, however, it has proven to be rather well-arranged and user friendly. The GUI is basically identical to the LOCOPIAS on-board loading software, which is derived from PIAS.

With this option you enter the list of loading conditions, which can be added, removed, copied and modified from here. This list contains the following columns:

With this cell a loading condition can be locked; it will become grey then, cannot be changed anymore, and is only available for copy purposes. Locking a condition can be useful to protect special conditions from unwanted changes.

Caution: if in a loading condition weight items from the common list (which will be introduced later on) are used, then changes to these items will nevertheless have their effects in the locked loading condition.

The menu bar of this list contains these functions:

An input window appears with all weight items for this loading condition. If weight items in the common list are defined as being a part of light ship, the first row will contain the sum of these items. This is the total light ship weight, which cannot be modified here — after all, how would such a modification be distributed over the many constituting components? If for the project weight groups are in use (please refer to Weight groups for that) that the list also contains rows with the sub totals per group. If a color is assigned to a group then this sub total is printed in that color.

The volumetric properties of the tanks always matches those from Layout where those tanks are defined. Weight group and density are connected by default to the design weight group and design density as defined in Layout. Any changes in Layout will then update these data in Loading. For each individual tank in Loading, specific weight group and/or density may be given. In this case the connection to Layout will be cut, for that specific tank. Such connected parameters are indicated by a yellow background cell color.

This list of weight items contains quite many columns — scrolling will bring you to the rightmost columns — which are:

The name of the weight item.

If the temperature corrections functionality has been purchased then one can double-click on the name of a tank to enter the temperature corrections menu. See Product, temperature and density for more information.

If a weight item is created by a loading tool, then it is assigned a ‘type’, e.g. ‘tank’, ‘crane’ or ‘containerbay’. In most cases the cells of a weight item of such a ‘type’ cannot be modified manually, after all those are being managed by the loading tool. An exception is a weight item of the ‘tank’ type, from which weight, volume, filling percentage or density can be entered, after which the other parameters (including COG) will be adapted automatically.

A weight item can be switched from such a ‘type’ to a regular (loose) weigh item with the <Space bar>. A ‘tank’ type of item has — if this functionality has been purchased — yet another option, which is the ‘flooded tank’, which is a tank in open connection with the sea.

Different people have different visions on how to take Free Surface Moments (FSM) into account. The preferred method can be entered here, with a choice between:

If a deviating FSM has been chosen, a !-symbol is printed in the output at the FSM with the option chosen. At the bottom of the page or weight list is a statement of the chosen options. Caution: this setting is not applicable for calculations including the shift of liquid effect (as discussed in (Damage-) stability including the shift of COGs of liquid), in which case always the real behaviour of the liquid is taken into account.

In the ‘Measured’ column a Sounding, Ullage or Pressure can be specified, as long as a sounding pipe and/or pressure sensor is available. With the columns ‘Trim sounding’ and ‘Angle sounding’ the trim and angle at the time of “sounding” can be specified. Note: The ‘Measured’ column contains the measured value associated with the specified trim and angle. Other data, i.e. columns, such as weight, volume and centre of gravity are determined at trim zero and angle zero.

If this functionality is not purchased then the ‘Measured’ column is only applicable to ‘grain hold’ weight items only, and depicts the Ullage, which is the distance between the top of the coaming and the grain surface. This column is only available if configured so in the Loading settings, see Settings intact stability.

Furthermore, this menu contains quite some upper bar functions:

Loading conditions for design situations are often made with a uniform filling for each type of tank content, e.g. in departure conditions the fuel oil and fresh water tanks filled for 98%, and waste water for 10%. Modifications for the whole weight group can be easily applied via modifing the appropriate value on the sub total line. Possible modifications are: ‘FSM type’, ‘Weight group’, ‘Tank filling’ and ‘Density’. Do note that with ‘undo’ it is possible to restore the modification.

It has already been discussed that weight items can be of the ‘tank’ type, then they are linked to the shape of a compartment as defined by Layout. To use a tank as weight item it should be ‘read’ into the list of weight items. With the menu bar option [Add missing tanks], as described in Define/edit weight items, all missing tanks will be added. A tank can not exist twice in a loading condition, not even by means of the common list.

With Config general PIAS settings are specified, while here in Loading, with the option ‘Loading project settings’ Loading-specific settings can be made. But calculations of stability and strength be carried out in practice for very many different situations, and therefore it may be necessary for specific load conditions to deviate from the standard. You can with this option. If it is selected, it displays a popup window with several sheets for different topics that are discussed in the following paragraphs.

If there are multiple windcontours available, then for each loading condition the appropriate wind contour can be selected. That can be done here; a list appears from which a selection can be made of the contours as defined in Hulldef.

In Hulldef multiple loadline drafts might have been defined, such as for ‘summer’ or ‘fresh water’ (see Maximum drafts and minimum freeboards). Here, for this particular loading condition, can be chosen which of those drafts should be included in the assessment of the condition. Furthermore, in Hulldef also minimum or maximum drafts specified (see Draft marks and allowable maximum and minimum drafts). If these are defined, here it can be selected which of those is applicable to this loading condition.

This option indicates the density (specific weight) of the outside water. Either a specific value can be used, or the standard value as defined in in Config ( Density outside water).

At the definition of intact stability requirements (see Definition and selection of stability requirements for that) can be specified which is the selected one. That one will be used for the stability assessment of all loading conditions, but occasionally a loading condition must be tested against other requirements. That can be set here. To do so, choose ‘alternative intact stability requirements’, and select the stability requirement which applies to this loading condition. Obviously, only requirements which have been defined, and are valid for intact stability can be selected.

This option indicates which set of maximum allowable bending moments and shear forces are used for the longitudinal strength calculations. There are two possible options:

See Definition maximum allowable shearforces and moments on how to define these criteria.

Here an additional heeling moment can be given, which is accounted for as a correction on the TCG of the displacement. This implies that this moment will be multiplied with the cosine of the angle of inclination.

Here the heeling moment (in tonm) due to the shift of grain can be specified. In case of grain, if stability critaria are in use ‘with grain moment’, then this moment is used in the stability calculations.

Here can be specified whether the vessel is grounded on a single point, the location of that point (in ship coordinates) and the water depth at that location. To be somewhat more precise, the mechanism is that the ship is potentially grounded, so the local draft at the grounding location can be less than the water depth (in which case the ship is not grounded at all), but cannot be more. This grounding effect is included in all computations of Loading, while in the intact or damage stability calculation an extra page will be added with the reaction force as a function of the heeling angle (if that option has been switched on in there respective Output settings tab page). The grounding effect will only be taken into account with intact and damage stability calculations with the free to trim effect (see Stability calculation method)

Additional to the regular stability output a polar diagram is plotted, which shows for each anchor chain angle the corresponding maximum anchor chain force which is still allowed by the anchor-handling stability criteria. See the example in Maxchain, Polar diagram with maximum allowable anchor chain forces for a particular loading condition. By the way, for this option it is not required to select other than standard stability criteria.

Here the criterion can be selected to which the line of sight must be tested.

Here the speed and delta displacement for the resistance-trim graph can be set.

If the front page is selected for output (at the Intact tab page), then here eight lines of free text can be given. In order to really include a line, the tick box just before it should be selected.

If the temperature corrections functionality has been purchased then by double-clicking the name of a weight item, of type tank, in a loading condition, the following menu can be opened. This menu contains all the necessary parameters for processing temperature corrections.

For the calculation of the cargo weight of heated hydrocarbons, the following conversion tables are available:

In case a conversion table other than No temperature correction is selected, this is recognisable in the weight item list by means of the yellow background colour of the name and weight of the weight item.

Under the [Damstab] option in the loading condition menu, or the weight item list three sub options can be found:

A maximum of 3000 damage cases can be defined. A damage case is a collection of compartments, as defined with Layout, which will be damaged simultaneously. After choosing this option a window appears where damage cases can be defined, and which is fully discussed in Input and edit damage cases.

In general, damage cases are not chosen at will, they are derived from the extent of damage as laid down in rules and regulations instead. For that purpose PIAS contains a specialized functionality, which is discussed at Generate damage cases on basis of the extent of damage.

A maximum of ten stages of flooding can be defined. A stage of flooding is a percentage of the weight of the contents of the damaged compartments in the final, this is 100%, stage of flooding. 0% stage of flooding means the compartments are not flooded at all, so this is exactly as the intact loading condition. The 100% stage of flooding is included automatically and need not be defined explicitly. The stages here are the same as defined in Hydrotables, see Define intermediate stages of flooding. Incidentally, there are many more considerations and possibilities regarding intermediate stages, which are discussed in Internal flooding in case of damage, through pipe lines and compartment connections.

A loading condition is essentially nothing more than a set of weight items (including their properties, such as name and Center Of Gravity), Those weight items can be entered in a loading condition, however, in practice there ar emany loading conditions, which have quite some weight items in common. It is beneficial if these items can be managed commonly, which is offered by the ‘common list of weight items’. This is a small database of weight items which can be used in multiple loading conditions. Everywhere these weight items are applied they are the same, which implies that a modification of such an item in one loading condition is directly transferred to the same item in another loading condition. So, the are not copied, the are being referred to.

The use of the common list is quite handy for weight items with a certain amount of communality, such as (obviously) the light ship (or its components) and deck loads or tank filling which occur in multiple loading conditions. However, its use is not obligatory, it is a tool, not more. In principle all weight items can directly be entered in the loading conditions, however, with the tiresome effect that later changes will have to be processed manually in all loading conditions. With the common list you save yourself these troubles, and reduce the change on errors.

The common list is simply a list of weight items, just as a loading condition has one. So, the input window of the common list is similar to that of a loading condition, as discussed in Define/edit weight items. Differences are:

Also the available upper bar functions have all been discussed with the loading condition list, with the exception of:

| Weight(1) | VCG(1) | LCG(1) | TCG(1) | Aft boundary(1) | Fwd boundary(1) | Component name(1) |

| Weight(2) | VCG(2) | LCG(2) | TCG(2) | Aft boundary(2) | Fwd boundary(2) | Component name(2) |

| 10.125 | 8.754 | 24.20 | -0.52 | 20.1(2) | 31.2 | Tandwielkast |

| Weight(N) | VCG(N) | LCG(N) | TCG(N) | Aft boundary(N) | Fwd boundary(N) | Component name(N) |

| ... | ... | ... | ... | ... | ... | ... |

| 0 | 0 | 0 | 0 | 0 | 0 | stop |

In this section the merits will be discussed of the several Loading computations: intact stability, damage stability, longitudinal strength and torsional bending moments.

At this tab several output options can be selected. From the listed components it can be specified whether they should be included in the output. If output for a selected option is still not produced, the reason might be that the option is not purchased or otherwise not available.

The option ‘Front page’ adds a front page to each stability calculation, which contains:

With the option ‘Moments of inertia of tanks’ an additional page with the volumetric moments of inertia of the filled tanks is printed.

This tab page facilitates in the output options for the longitudinal strength calculation.

At this tab several output options of the damage stability calculation can be selected. From the listed components it can be specified whether they should be included in the output. If output for a selected option is still not produced, the reason might be that the option is not purchased or otherwise not available.

Here you can specify whether a full or short ‘Cargo/ullage report’ is desired. See Cargo/ullage report for more information.

To perform the stability calculations, it will be obvious that all the ship properties should be fully specified, not only hull shape and compartments, but e.g. also the light ship weight and openings. In addition, the following properties must also be set correctly in order to be able to make a complete stability calculation:

The intact stability output contains the following parts:

However, this is the standard output, with the different settings of Loading it can be extended or limited significantly.

Longitudinal strength comprises the longitudinal distribution of shear forces and bending moments, and, if set, deflection and elevation. A hogging moment is positive, a sagging moment negative. A positive shear force at a position indicates that behind that position the aggregated buoyancy is less than the aggregated weight. These computations are based on the longitudinal distribution of buoyancy and weight.

Each weight item is assumed to have a linear distribution between aft and forward boundary, in such fashion that the longitudinal center of gravity (LCG) equals the user-specified value. For example:

Have distributions according to the figure below.

If the LCG is not within the middle 1/3 between the forward and aft boundary, then the distribution becomes partially negative. In some cases this is realistic, for example with a crane where the center of gravity of the load is even completely outside the boundaries, and sometimes it is unrealistic. Therefore it is verified at the longitudinal strength calculation whether the LCG is outside the 1/3 boundaries, and if so a warning is displayed. Also with tanks that are strongly curved in the longitudinal direction it might occur that the LCG exceeds these 1/3 boundaries. This is always considered unrealistic — the distribution of liquid in a tank can never give negative values in the weight distribution — so in these cases the aft or forward boundary is adapted in order to bring the LCG exactly to the 1/3 or 2/3 location.

If maximum allowable bending moments and shear forces have been defined (to do so please refer to Definition maximum allowable shearforces and moments), the actual bending moments and shear forces will also be presented as percentages of the maximum values.

Then the conclusion is drawn, which represents whether all moments remain below the maximum allowable values. Please note that evaluation of actual moments against maximum allowable values is also performed at intermediate values in-between the read-out points. The maximum allowable value at these intermediate positions is found by lineair interpolation. This evaluation at intermediate points might affect the overall conclusion. So, it might occur that all read-out point values are less then the maximum allowable values, while the conclusion still is drawn that this loading condition does not comply. Somewhere between the read-out points the interpolated maximum will be exceeded in such a case.

There is also the option to calculate and output the so-called ‘Envelope curve’. With this option, the envelope upper and lower limits are calculated of the occurring shear forces and moments based on the curves of the selected loading conditions. This envelope curve can be used to determine how strong the ship should be at certain longitudinal positions. Thus, it is really a design tool.

With this option for all combinations of selected damage cases, selected loading conditions and intermediate stages of flooding damage stability calculations will be produced. Suppose there are three loading conditions, five damage cases and two intermediate stages, then 3 x 5 x (2+1) = 45 damage stability calculations will be made. A regular output contains the following data:

The first line indicates to which side the vessel is heeling, SB or PS. The module automatically determines the side with the worst stability, however, this can also be configured otherwise, please refer to Calculate damage stability with a heeling to for this setting. Subsequently, for every defined heeling angle the following particulars are printed:

When instead of, or next to, these columns the text ‘The vessel sinks’ is printed, this indicates that a non- watertight or non-weathertight opening is submerged at an angle smaller than the statical angle. Or that the total weight exceeds the total buoyancy.

With this option the time can be calculated which is needed to let a compartment be flooded through a cross-flooding arrangement. The purpose of this option is similar to the method of IMO MSC.362(92) (formerly IMO res. A.266), with the difference that the IMO resolution gives an approximation method, while this PIAS option applies a stepwise calculation (a time-domain simulation) — based on Bernoulli's law — which yields in general more accurate results. This application is covered by section 4 van MSC.362: “As an alternative to the provisions in sections 2 and 3, and for arrangements other than those shown in appendix 2, direct calculation using computational fluid dynamics, time-domain simulations or model testing may also be used”. The parameters which are necessary for this option must be specified at ‘complex intermediate stages of flooding’, please refer to Complex stages of flooding (before 2023).

The torsional moments calculation is always performed for the upright vessel. Because of round-offs in the calculation and because the vessel might have an initial heeling in the loading condition, a residual moment at the end of the vessel might occur. To correct this the residual moment is linearly distributed over the total length of the vessel. The option to make torsional moment calculations for a grounded vessel has not been implemented.

The generated output of the calculation shows successively:

Delivers a report where for all tanks — and then for all measuring devices, i.e. sounding pipes and pressure sensors, in the tank — at trim zero and angle zero, the current sounding, ullage and/or pressure is calculated based on the current volume.

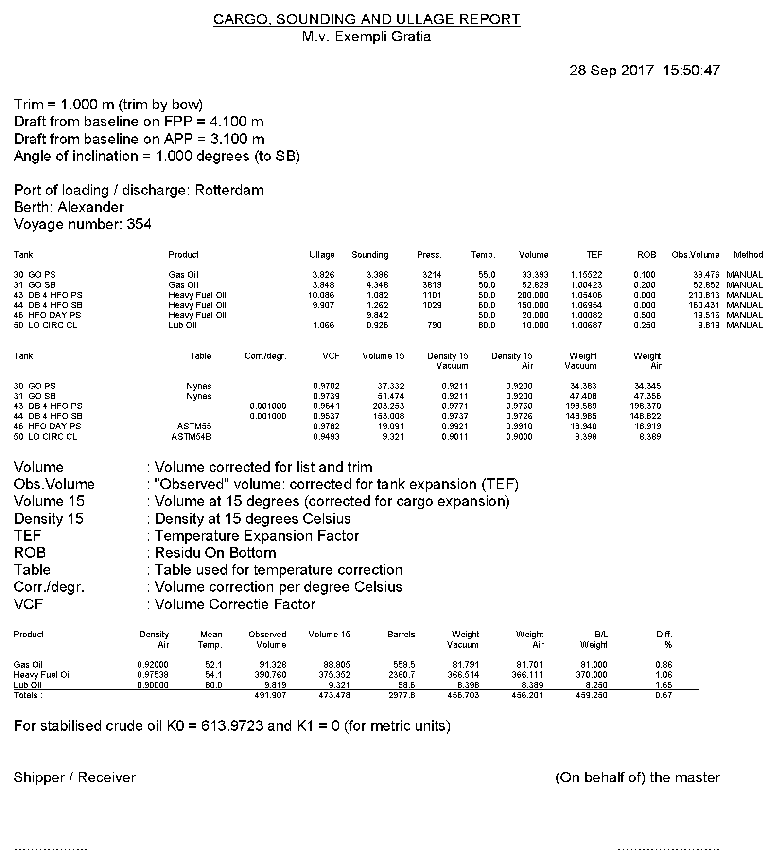

This option allows you to print an overview of all onboard cargoes, including their weight, temperature effect, sounding and ullage etc., see example below. This list includes only those tanks of which the detail particulars (as discussed in Product, temperature and density), at the second row ‘Include this tank in ullage report’ is switched on. Before this report is created some more questions might be asked, such as the Bill of Lading weight. Note that the weights of the Bill of Lading are only useful if the ‘Product (substance)’ is defined.

In Config the general settings for damage stability can be selected (see General settings damage stability), while here settings specifically for deterministic damage stability (which, after all, is computed by Loading) can be given.

With the general ship input data in Hulldef, paramaters can be given for maximum allowable chain forces for anchor-handling vessels, zie Anchor handler particulars. In that Hulldef menu a few sets of criteria can be selected, either NMD2007, BV2014 of IS code 2020. If the BV type is chosen, the polar plot can be produced for a user-specified angle of β (please refer to Input of specific ship data for its definition) which can be set in this menu.

Purpose and use of ‘weight groups’ is discussed in Weight groups.

The modus operandi of the stability criteria system is discussed in Stability criteria for intact stability and damage stability, and the specific menu to enter stability criteria in Manipulating and selecting sets of stability criteria. In this menu it can be indicated which of the stability requirement sets is valid for the assessment of the intact stability. This is then used for all loading conditions, but it is also possible to assess some conditions against other requirements, as described in Stability requirements.

In this overview screen all created longitudinal strength criteria are displayed and how many points for the respective boundary lines have been specified. By double-clicking on a boundary line column one can modify the corresponding boundary line.

The option standard criteria allows for easy switching between different strength criteria for multiple loading conditions, if Strength have been selected for standard strength criteria.

The defined values are used in the assessment of the longitudinal strength and torsional moments calculations.

With option [Output] the input values can be printed to paper.

The percentages, which are shown in the output, are normally calculated from the zero line, but it can happen that the upper and/or lower limit are entirely or partially below or above the zero line. In such a situation the zero line is no more insight and a fictitious zero line is determined halfway between the given upper and lower limit. This allows the percentages to be determined as before, but in relation to the fictitious zero line instead of the actual zero line. It is possible that the lower limit is above the zero line and that the upper limit, which is also above the zero line, starts at a length position greater than the lower limit. In this situation, no percentage can be determined, because determining the fictitious zero line is dependent on upper and lower limit.

In this menu the maximum allowable boundary line can be defined as a function of the length.

The following points must be taken into account when defining the maximum allowable boundary line:

Using the menu bar function [Lininterpol], intermediate longitudinal positions can be interpolated linearly.

The used abbreviations used in this menu are:

Purpose and use of ‘sections tank arrangement’ is discussed in Sketches of tanks, compartments and damage cases.

PIAS contains specialistic functionality for objects which are moored with multiple anchors. It finds equilibrium in the horizontal plane, while the vertical chain forces are included in the stability computations. In the menu the relevant chain parameters can be given. However, this menu is only available for those who have actually purchased this functionality.

For the purpose of the calculation of the longitudinal sagging — such as is included in the longitudinal strength calculation if the including calculation of sagging option is switched on, see Settings longitudinal strength — the moment of inertia of the midship structure must be specified. That can be done here, in fact, for multiple cross sections that can be specified, so that the effect of the longitudinally varying moment of inertia on the deflection can be accurately taken into account. If the variation in moment of inertia can be excluded than it will suffice to enter the midship moment of inertia only. To be exact, in the two colums you specify:

This is a bit of an outdated option, however, it still might occur that a longitudinal strength manual is required which also contains a scheme for the manual calculation. In that case tables of shear force and moments of only the buoyancy might be needed. With this option (if purchased) those tables can be produced. Calculation will be performed for user-specified drafts, for all longitudinal positions for which maximum allowable bending moments and shear forces are defined. After this option has been selected the following data can be specified in a menu:

The output is not designed for printing directly to paper, after all, some post-processing will be done anyway.

See Ship-specific settings for ballast advice.

This facility is intended for simulation of RoRo operations, and is discussed in Generation of loading conditions for simulation of Ro-Ro operations.

This option can be used to perform multiple kind of calculations in one single run.

In this menu can be specified which computations should be made and printed. For each type of computation also a page numer and chapter name can be given, which will be printed at the bottom of each page. The left column, selected specifies whether the output of that line is actually included in the output to be produced. The menu bar contains the function [layout], which can be used to choose from two kinds of output sequences. The first option is [Type of calculation], where first for the first type of calculations all loading conditions are printed, and then for the second type of calculations all conditions etc. The second option is [Loading condition], where first for the first loading condition all types of calculations are printed, then for the second condition all types etc. The chapter name as given in this menu is only used with the ‘Type of calculation’.

Backups of the Loading data can be made and restored here. Here is also the option ‘Quit module without saving the data’. See for the details Data storage and backups.